Our stainless-steel processing units can be used in a wide range of production lines. It is a custom solution that can consist of a range of tanks, CIP solutions, tube systems and agitators. Furthermore, the unified processing plant can be controlled by a PLC.

Complete Process Units in Stainless-Steel

At JH Stålindustri we do not simply manufacture any old tank. We offer a complete solution adjusted to the needs of the individual customer. With our experience working with many different industries, we can offer unique design and delivery of complete process plants for any business. The tanks are manufactured in close corporation with the customer, so the final plant will meet the precise requirements that are placed required in terms of production, sanitation, and functions.

Expert Consultation for our Customers

At JH Stålindustri we are industry leaders in terms of experience with tanks and process equipment. This gives us the confidence needed to be able to give in-depth advice about every aspect of the process units we manufacture. We carefully listen and consider the needs of each customer and then provide advice and strategies to come up with a complete solution. This includes tanks with CIP plants, agitators, and PLC control.

Scraped Surface Heat Exchanger

Through the years we have made a lot of processing units for the food industry with built-in scraped surface heat exchangers. At JH Stålindustri we have developed the Rotapro scraped surface heat exchanger which is ideal for a process unit the need for heating or cooling of high viscosity products. The scraped surface heat exchanger is an integrated part of a wide range of process units we produce at JH Stålindustri because it can efficiently process products in a gentle way.

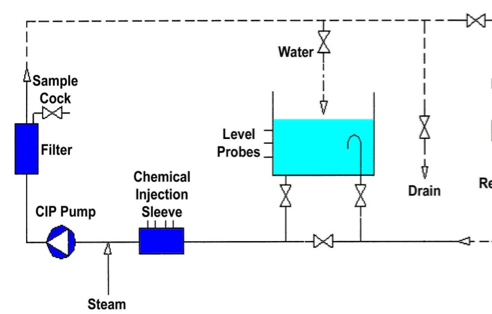

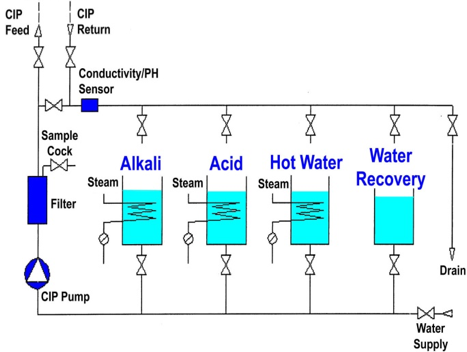

CIP plants

CIP plants are often part of the complete process unit. At JH Stålindustri we have developed our own “JH CIP Unit” that can efficiently cleans the entire processing plant. JH CIP units are made using a stainless-steel bottom frame, which is then mounted with the necessary number of tanks as required by the task. The unit can be stationary or mobile depending on size and capacity. The JH CIP unit can be “one string” without reclamation, or “several stringed” with reclamation.