A mobile tank is a flexible solution when a business is looking for tanks that can easily be moved from one process line to another. The main characteristic of mobile tanks and vessels is that they are placed on a frame with wheels or on brackets for forklift transport. Thus, they are more mobile and can be moved around in the production line or the laboratory. In terms of max capacity, stainless-steel mobile tanks and vessels have an upper volume limit of 1000 liters.

Mobile Tanks and Vessels Customized for the Production

A mobile tank can be manufactured in many ways and are made according to its purpose and use. That is why we at JH Stålindustri always take the customer’s current environment as our starting point for our design and then adjusts the tank’s design to perfectly fit your scheme. We can provide stainless-steel mobile tanks and vessels that have options such as:

- With or without cooling and heating cloak

- With or without insulation

- Requirements for agitators

- Access conditions and ATEX

- Valves and instrumentation

- PLC control

Mobile Tanks and Vessels can be Manufactured as Pressure Vessels or Process Tanks

At JH Stålindustri, we are experts in crafting stainless-steel tanks to work with and without pressure. We are also able to make mobile tanks and vessels as both process tanks and pressure vessels. In case you are unaware, the difference is as follows:

- Process tanks – less than 0.5 bar

- Pressure vessels – more than 0.5 bar

Whether there is a need for a pressure vessel or a process tank, we can adjust the design of each mobile tank to meet the desired specifications and requirements. There are few in the business who can provide that flexibility.

Special Manufacturing of Mobile Tanks and Vessels for Various Industries

Our stainless-steel mobile tanks can be manufactured to use special alloys and are designed with high surface requirements including electro polishing. No matter the industry, we can manufacture the tank to meet even the hardest requirements. For example, we produce mobile tanks that are essential in industries such as:

- The dairy industry

- The food processing industry

- The pharmaceutical industry

- The chemical industry

JH Stålindustri Is the Common Choice for Mobile Tanks and Vessels

At JH Stålindustri we manufacture stainless-steel tanks to meet the requirements and specifications of our customers. We place the most importance on making sure that all the standards are met, and that our customers are left with a high-quality tank. That is why our customers can expect:

- That we make sure we are 100% aware of the customer’s needs and requirements for the tank

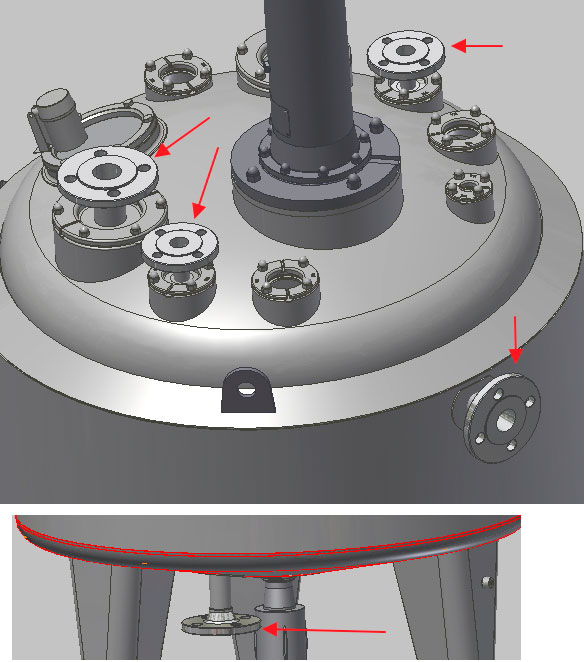

- A constant effort is made to make sure the customer understands all the technical details about the tanks. We may provide 3d diagrams to give a visual cue.

- Documentation for the manufacturing of the tanks. Among this material will be welding certificates, surface checks, pressure checks, drain tests and much more.

Our Craftsmen are certified

To manufacture premium mobile tanks using stainless-steel is a craft which few have mastered. Luckily, our welders are among this select few and possess a drive to deliver excellence. Our craftsmen are all certified in accordance with the PED requirements and can work with:

- Different materials

- Different welding methods

- Different goods thickness

The certifications are valid for 3 years, and therefore we can guarantee that our blacksmiths are always up to date with the latest working methods. It is your guarantee of a job well done.

Contact JH Stålindustri today if you want to know more about our stainless-steel mobile tanks or our procedures. We can be reached via the telephone at +45 86 47 90 44 or by e-mailing us at jhstaal@jhstaal.com