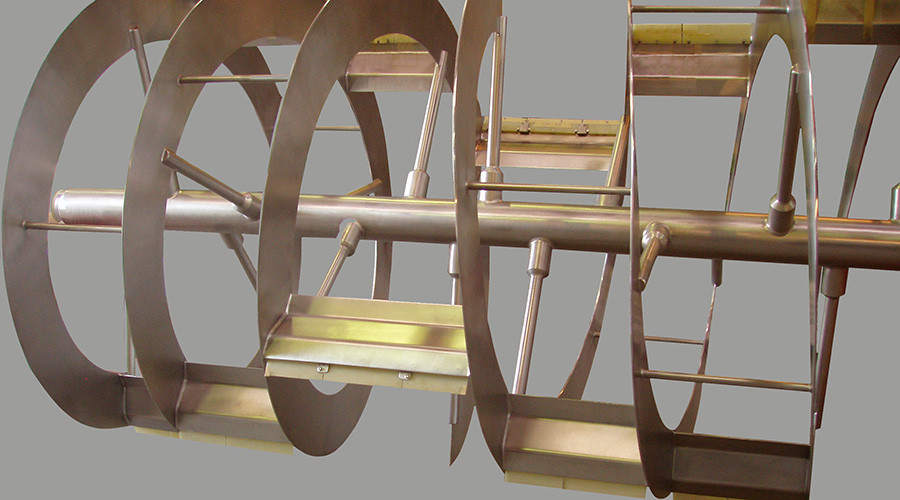

JH Stålindustri has developed complex and efficient agitators. We can manufacture agitators for the processing of high viscosity products where there is a demand for a gentle treatment of the product.

Specially Adjusted Agitators for Stainless-Steel Tanks

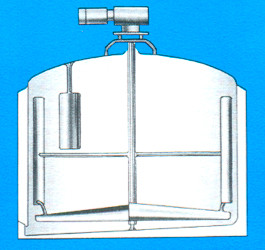

At JH Stålindustri we have extensive experience with manufacturing a wide range of stainless-steel agitators for both pressure vessel and process tanks. We can provide solutions in which we will produce both the tank and agitator. However, we can also provide agitators that suits the customer’s existing tank.

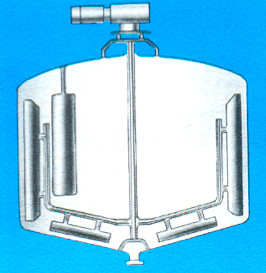

At JH Stålindustri we customize our agitators so that they can be placed in any tank no matter the type or size. Our years of experience in this line of work makes us capable of calculating the factors that are important to the customer, and then finding an optimal agitator solution.

Powerful Agitators for Stainless-Steel Tanks

Agitators can be a fixed onto any kind of tank. The manufacturing of good agitators depends to a large extent on the adjustment to the specific tank as well as the tank’s uses.

For example, we have manufactured tanks for the food industry in which high viscosity products required powerful agitators with high pumping capacity and a high momentum at the start or were capable of changing direction.

Our many years of experience in this line of work makes us capable of manufacturing and advising clients about complex agitator solutions.

Creating the Right Agitator Solution

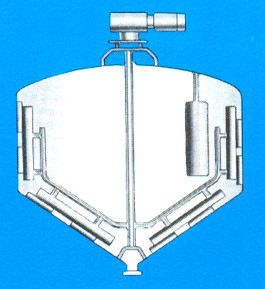

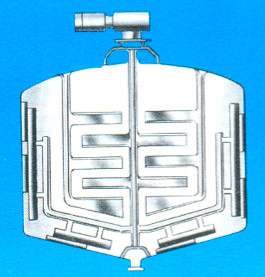

While it may seem easy, ensuring correct agitator is used in a tank is an incredibly challenging process. Some of the many things to account for are:

- Is there a need for heating or cooling of the product?

- Are there bigger particles in the product that need to be mixed in?

- Are wet and dry particles going to be mixed?

- Does the product have high viscosity?

- Which effect should the agitator operate with?

- How many scraping blades are necessary?

- Where are the scraping blades going to be placed?

- Will the tank have bottom equipment?

- Is the most optimal choice a side mounted or a top mounted agitator?

At JH Stålindustri we have many years of experience in making tanks and agitators. That is why we can help you to calculate all these factors to ensure an efficient stirring with the right agitator solution.

JH Stålindustri Is the Number One Choice for Stainless-Steel Agitators

At JH Stålindustri we manufacture stainless-steel agitators to meet the requirements and specifications of our customers. We always ensure that all standards are met, and that our customers are left with a high-quality product. That is why our customers can expect:

- That we make sure we are 100% aware of the customer’s needs and requirements for the tank

- A constant effort is made to make sure the customer understands all the technical details about the tanks. We may provide 3d diagrams to give a visual cue.

- Documentation for the manufacturing of the tanks. Among this material will be welding certificates, surface checks, pressure checks, drain tests and much more.

Our craftsmen are certifed

To manufacture agitators to meet each unique tank’s needs is an incredibly challenging task. Luckily, our welders are among a select few and possess what it takes. Our craftsmen are all certified in accordance with the PED requirements and can work with:

- Different materials

- Different welding methods

- Different goods thickness

The certificates they have are valid for 3 years, and that is why we are confident that our welders are always updated with the newest working methods. This should also give you confidence that you are working with the best.

Contact JH Stålindustri today if you want to know more about our agitators or our procedures. We can be reached via the telephone at +45 86 47 90 44 or by e-mailing us at jhstaal@jhstaal.com